Liquid silicone rubber molding(LSR) is a manufacturing procedure used to create automotive parts such as seals, gaskets, and other components to equip automotive vehicles. LSR is a type of silicone that remains liquid at room temperature, but it can be quickly injected inside a mold to create a part bearing precise dimensional tolerances.

The Advantages of Liquid Silicone Rubber Molding

One of the main advantages of LSR molding is its ability to produce parts with high levels of detail and accuracy. The liquid nature of the silicone allows it to flow inside the tiniest crevices of a mold, meaning that even the most complex shapes can be produced easily. On top of it, LSR has excellent resistance to heat and cold, making it suitable for use in automotive applications where parts can be exposed to extreme temperatures.

Another advantage of LSR is its high durability and resistance to wear and tear. Automotive parts made from LSR can withstand the rigors of daily use and exposure to the elements, such as water, dust, and chemicals, without degrading. This means liquid silicone rubber molding parts have a longer lifespan than those made from traditional materials such as rubber or plastic, which can become brittle over time.

LSR molding for automotive parts

Using Liquid Silicone Rubber Molding for Automotive Parts

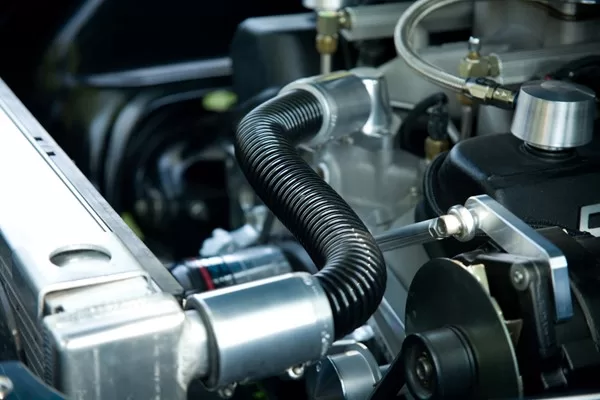

LSR is pretty versatile and can be used in a wide range of automotive applications. Some examples of automotive parts that are commonly produced using LSR molding include:

Seals: LSR is a popular choice for making seals and gaskets, as it can be used to create a tight seal that will not leak. These parts are commonly used in engines, transmissions, and other systems to prevent the leakage of fluids or gases.

Hoses: LSR is also used to manufacture hoses and tubing for various automotive applications, such as coolants, brakes, and fuel lines.

Keypads: LSR is the perfect choice for making keypads because of its excellent resistance to wear and tear and its ability to withstand exposure to liquids and other materials.

Lighting: LSR is also commonly used to produce car lighting components, such as LED light housings, lenses, and seals.

Interior parts: LSR is used to manufacture various internal components such as door handles, armrests, and seat-adjustment knobs.

Overall, LSR molding is a versatile and reliable process for producing a wide range of automotive parts. With its high level of detail, precision, and durability, LSR is an ideal material for use in the automotive industry. With the increasing demand for LSR molded parts in the automotive sector, the use of LSR molding is expected to continue growing in the coming years.